Steam Jacket Kettles

GPE Kettle Styles

All GPE Kettle Styles Feature:

- Traditional high-polished sanitary finish

- Sanitary flanged rims

- All stainless steel product contact parts

GPE Kettle Outlet Features:

- Exclusive GPE designs permit shorter outlet fitting

- Sanitary Acme threaded or tri-clamp ferrule provided on stationary kettles

GPE Kettle Support Features:

- Stainless steel pipe legs with fixed floor flanges

- Available on stationary and tilting kettles

GPE Kettle Trunnion Style Features:

- Free-pouring spout

- Tilt handle on CD style

- Hydraulic tilting on CHD

Style of Steam Jacket Kettles

Style TA

Designed for heavy duty processing, this strong, reliable agitator kettle features twin shaft agitation with a GPE twin shaft gearbox. This deluxe agitator provides finger-like scraper blades which scrape side walls and swirl the processed material toward the secondary mixer for continuous, all-inclusive agitation. For ultimate sanitation, the TA features exclusive GPE quick-disconnect couplings which permit the entire agitator assembly to be taken apart in a few seconds. Available in 40 to 1,000 gallon capacities. USDA approved design.

Style RA

Designed for processing light to medium-heavy materials, this agitator configuration features a single anchor-type agitator frame with finger-type scrapers which carry processed material from kettle wall into two large "V" shaped baffle plates, providing "Figure 8" type blending action. Also features exclusive GPE quick-disconnect shaft couplings for easy removal and cleaning. Standard unit is available in 40 to 1,000 gallon capacities. USDA approved design.

Style DA/1 & DA/2

Incorporates the GPE double motion agitator design with counter rotating blades, which can be rotated singly or concurrently in the same or opposite directions. Agitator drive unit, mounted on channel shaped bridge support, is comprised of dual heavy duty hollow shaft gearhead motors in a piggyback configuration. Standard unit is available in 40 to 1,000 gallon capacities. USDA approved design.

Style INA

Designed to handle medium to heavy viscous materials containing solid particles that tend to settle or float, the GPE INA features a patented inclined single motion baffle/scraper mixer to provide a thorough, gentle lifting and folding action for uniform homogeneity of product. Agitator frame is readily removable; baffle is permanently mounted on drive support frame. Available in standard capacities of 60 to 300 gallons. USDA approved design.

Style INA/TA & INA/2/TA

These models are designed to handle medium to heavy viscous materials containing solid particles that tend to settle or float. The patented GPE twin shaft inclined agitation features dual heavy duty TA type mixing motion to provide a thorough, lifting and folding action for uniform homogeneity of product. Agitators are readily removable for cleaning. Available in standard capacities of 100, 200, 250, and 300 gallons. USDA approved design.

Style INA/2

The INA/2 kettle, with gentle inclined agitator mixing action, solves problems experienced with other style mixers. This patented agitator's lifting/folding motion thoroughly blends and mixes with positive action. Particles and ingredients are quickly dispersed through the batch, and held in suspension to insure homogeneity. USDA approved design.

Style SA (F)

For applications not requiring robust mixing, the SA (F) is designed for slow speed blending. The fluted frame-type agitator provides ideal product movement for holding or cooling applications. Standard sizes from 40 to 1,000 gallons with larger sizes available on application. USDA approved design.

Style NEM

Specifically designed for products requiring high shear mixing in addition to sweep type blending, the NEM has a high-speed propeller in the center bottom for fast wetting out and mixing combined with a counter-rotating fluted sweep-type scraper agitator providing thorough blending of finished product. Heavy duty piggyback drive offers long term maintenance free operation. USDA approved design.

Style N

The versatile GPE N can be used to cook and/or cool most pumpable products such as fruits, vegetables, beverages, syrups and confections, juices, meat, poultry and seafood products, soups, and stews. These kettles can also be used in the production of pharmaceuticals, cosmetics, and specialty chemicals. Addition of a mixer greatly extends the range of applications. The N steam jacketed kettles are heavy duty processing units available in standard capacities from 5 to 1,000 gallons and in other capacities by special order. This jacketed stainless steel kettle permits complete product draining and facilitates cleaning and sanitation. Standard material for the kettle body is Type 304 or Type 316 stainless steel with a No. 4 sanitary finish. Other specialty finishes are available upon request.

Kettle Options & Accessories

While the style of kettle you choose will have its own set of features, you also have the opportunity to choose from a few other options.

Instrumentation

Temperature recording and control can play a critical role in your processing technique. Our temperature sensing or control instruments can ensure you yield the desired results in heat transfer vessels. We offer:

- A wide variety of temperature sensing control and recording instruments

- Probe-type sensors for open kettles

- Stainless steel flush mounted sensors for scraper blade agitator installations

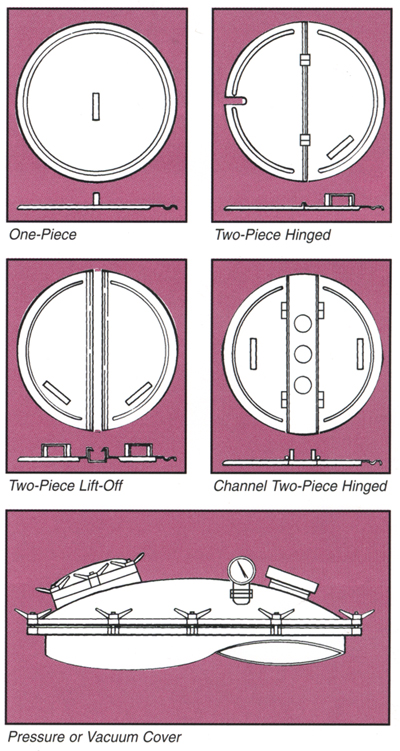

Covers

We offer various styles of sanitary covers for all types of GPE vessels.

- Two- or three-piece covers, either lift-off or hinged

- Furnished with special fittings or openings. if necessary

- Designed to include a vacuum/pressure style cover if required

Electropolishing and Finishing

We recognize the demand for high-quality, durable, ultra-sanitary finishes. We provide world-class mechanical finishes and can also provide electropolish finishes on all of our parts and products.